GAP, i.e. grinding disc, automotive and packaging

Grinding disc

These are our three main pillars of activity. We are a leader on the European market in each of these industries. Grinding discs are not only used for grinding, but also for cutting or making cuts. Angle grinders are one of the basic elements of maintenance workshop equipment.

How are grinding wheels made?

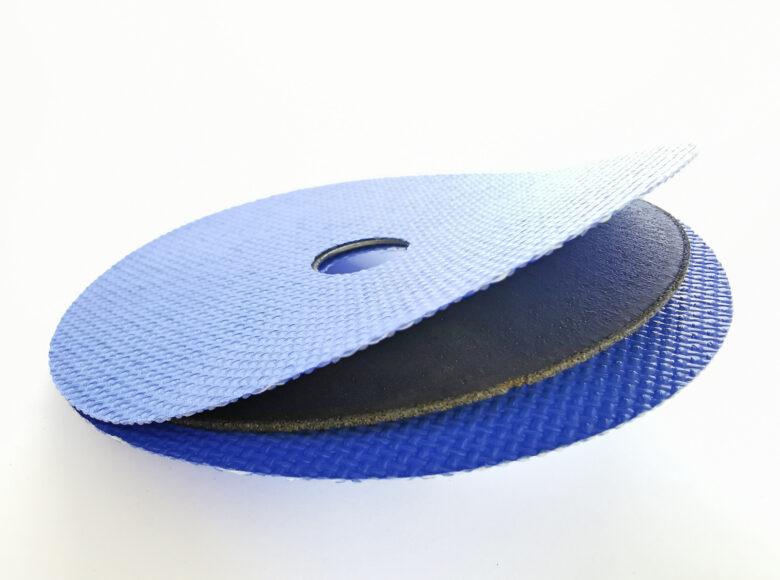

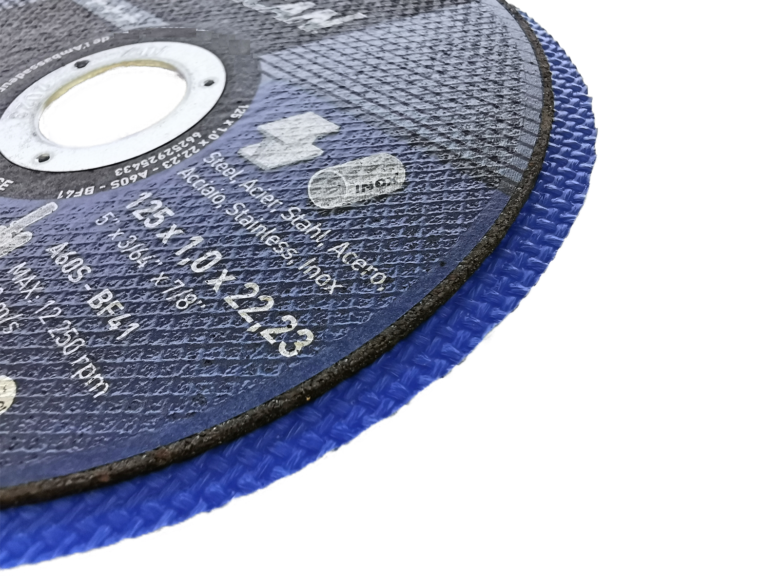

Grinding discs are made of a bond, most often resin, and abrasive grain. How can we help in this topic? The discs pressed in automatic presses are placed on stands with PTFE liner. Then they go through the drying process. After drying, they are transported to furnaces, where they are fired at temperatures up to 250 ° C. EDER PTFE liners guarantee proper degassing of the discs and do not stick to the discs themselves. After the firing process is completed, the grinding wheels are cooled down. After reaching the ambient temperature, the discs are removed from the stands, packed and shipped to customers. EDER PTFE liners are ready for further use.

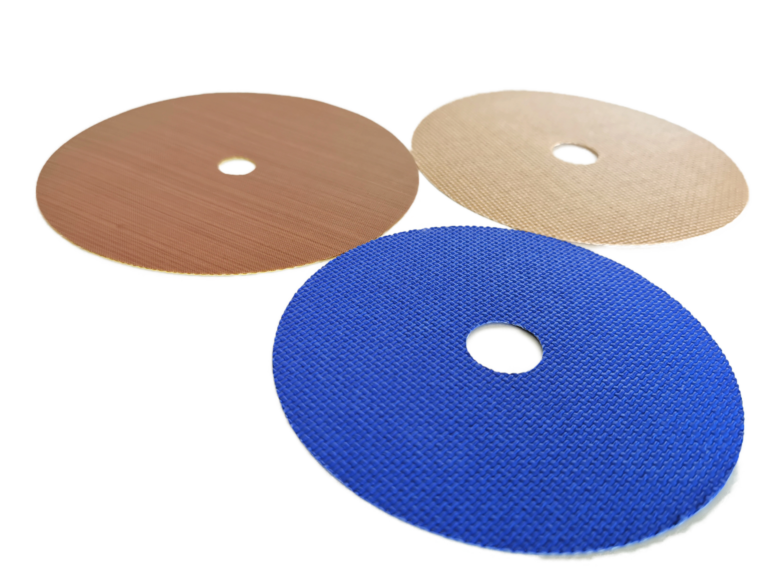

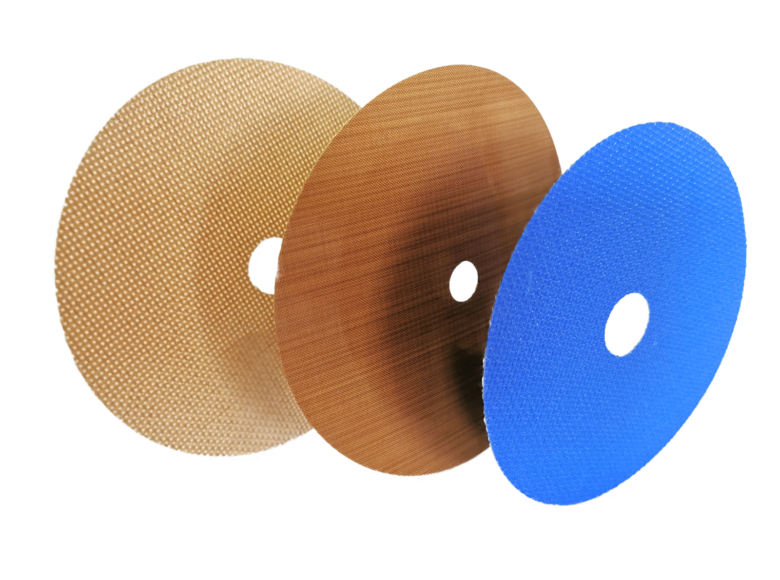

We offer two types of liners:

- standard ones that offer the best compromise between quality and price

- premium, for customers who follow the highest number of firing cycles without the need to replace PTFE spacers

Even the largest diameter of the PTFE spacer is not a problem for us. The largest PTFE liner made so far had a diameter of 2300 mm. Our plotter is equipped with an oscillating knife head. It is one of the most modern devices of this type in Europe with a cutting format of 2800mm x 5000mm. This means the maximum size of the processed material sheet is 2800mm x 5000mm.

Thanks to the technical advancement and high operating parameters of the device, the plotter cutting is fast, with a guarantee of very high quality edges. We can produce 20,000 PTFE liners per day.