GAP, i.e. grinding, automotive and packaging

Automotive

These are our three main pillars of activity. We are a leader on the European market in each of these industries. For decades, our smooth solutions have been helping automotive manufacturers offer car manufacturers the highest quality parts. The door seals of the most recognized manufacturers are vulcanized on our PTFE belts.

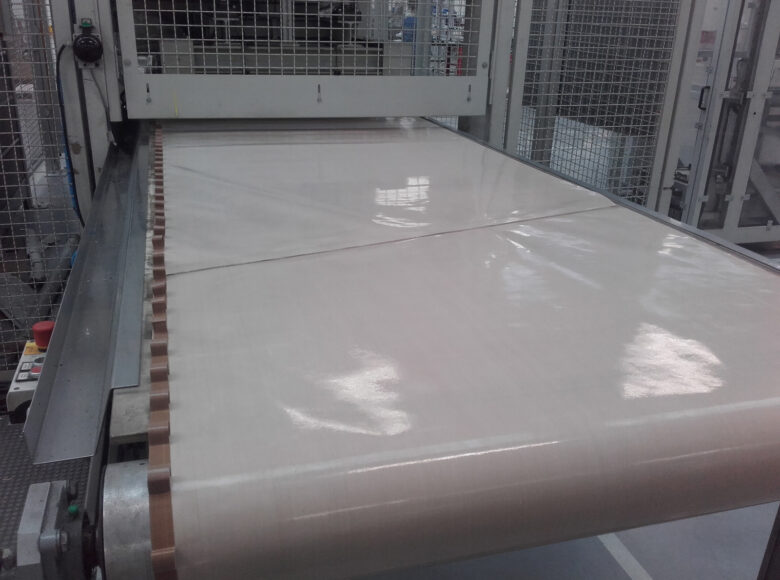

The production of artificial leather for car upholstery takes place in a continuous lamination system, also on our PTFE belts. In the continuous lamination process, perfect belt smoothness and an imperceptible joint are required. To extend the life of the PTFE belt, we suggest covering it with an EDROCK™ coating. EDROCK™ is the most modern coating of PTFE belts available from Eder. Thanks to specially selected fluoropolymers, it has the highest anti-adhesive parameters. It is more tight and resistant to penetration into the material. Under extreme operating conditions, the EDROCK ™ coating allows the belt to run longer. Thanks to the parameters of the newly created coating, the material remains free of dirt for longer, which contributes to faster wear of PTFE belts. The EDROCK™ coating protects glass / aramid fibers – responsible for the mechanical strength – against penetration of aggressive media. Continuous operating temperature: from -150 ° C to + 260 ° C.

Thermoforming of non-woven fabric for trunk liners is another element of Automotive where our smooth solutions are successfully used. Special coatings developed by us ensure perfect protection of the press plates.